■ ACMT/ 邱耀弘

Legend of special translate: two parts paper f “Introduction to Metallographic for Powder Metallurgy” were showed on Powder MetallurgyReview. Part I translated by Dr. Q and Part IItranslated by Dr. Dan of PIMA-CN.專案翻譯說明:本文章為刊載於英國國際期刊粉末冶金回顧(Powder Metallurgy Review) 的期刊中連載二期的技術文件,由PIMA-CN 的邱耀弘博士與鄧忠勇博士個別翻譯。

The Author 作者

Thomas F. Murphy, FAPMI, Scientist, Research &Development Hoeganaes Corporation Cinnaminson,NJ USA

文章出處︰ P39~49, Vol.4 No.1, © 2015 Inovar Comm unications Ltd, Winter 2015, Powder Metallurgy Review注意翻譯按照有關英式英文內容以更改為美式英文,請對照PDF 原文檔案。有錯誤與不懂之處。歡迎討論!粗體字為譯者補充說明。

譯者:鄧忠勇博士- 湖南英捷高科/ 湖南恆基粉末科技

技術總監,2015/05/06 助理編輯:邱耀弘博士

2 . Revealing and examining the microstructure of sample樣品的顯微組織的顯露與檢查

Metallographic analysis is primarily a collection of visual and imaging techniques. Therefore, the appearance of the samples must be accurate in order to gather correct and relevant information on the part or material. The examination of Powder Metallurgy (PM) materials presents several unique challenges to this accurate representation. The most obvious is ensuring the faithful representation of the pore structure. This is absolutely necessary and can be obtained only with correct sample preparation techniques.Correct preparation will also ensure the surface is free of disturbed metal and that the true microstructure can be revealed using etching, staining or optical techniques. The metallographic preparation and evaluation of ferrous PM parts is sometimes complicated by the presence of localized mixtures of multiple transformation products.金相分析主要建立在視覺和影像技術的基礎上,因此,樣品的被觀察區域一定要能精確地再現其實際顯微結構,這樣我們才能從中獲得關於樣品的準確資訊。粉末冶金材料對金相技術提出了一些特殊要求,顯然,準確地再現孔隙結構即為這種要求之一。對於粉末冶金材料來講,了解孔隙的結構是非常必要的,這只能藉助於正確的製樣技術。適當的製樣還能避免外來干擾元素的影響,再結合蝕刻、著色、偏光等手段,才能真實顯露出待檢材料的顯微組織。對於鐵基PM 製品而言,有時由於在局部區域混合存在有多種相變產物,會增加金相準備及評價工作的複雜度。

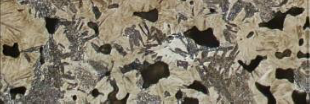

An example can be seen in P2-Fig.1, where the microstructure contains several transformation products. The cooling rate was the same for each region of this field of view so the presence of various microstructural constituents is not the result of any difference in cooling rate. There are several factors that contribute to this behavior.如P2- 圖.1 所示,顯微組織中就包含有幾種相變產物。對這塊視場中的每一塊區域而言,其燒結冷卻速度是完全一樣的,所以各種不同相組元的形成並非是由於冷卻速度的差異造成的,而是另外一些因素共同作用的結果。

2.1Alloying and the PM process合金化與粉末冶金過程

Alloy composition of the powder mixture, the method used to manufacture the base powder, and the sintering conditions of temperature, time, and atmosphere all define the distribution of the alloying additives and, consequently, the local alloy harden-ability. The section size, cooling rate in the sintering furnace and any secondary heat treatments determine the final microstructure. In most cases where particulate alloying additives are used in the powder mixture, the chemical composition of the material through the part volume is not homogeneous. The harden-ability is variable on a local scale, where the regions containing the highest additive content have the highest harden-ability.合金的組成來自粉末的混合,包含基地粉末、燒結條件的溫度、身溫與保溫的時間以及氣氛,加上添加的合金物如可增加硬化能的元素。另外對於產品燒結表面的斷面的尺寸、冷卻速率以及二次熱處理都影響到產品的顯微結構。

The alloying of ferrous Powder Metallurgy alloys is accomplished using several different techniques, some unique to the PM process. This alloying involves incorporation of various amounts of elements such as copper, molybdenum, nickel,chromium, manganese, silicon and/ or others into the iron-based particles, either during the manufacture of the base powder or as ingredients in the powder mixture. The choice of the additives is determined by the desired properties of the part and the tendency of the element to form oxides that are stable at the intended sinteringtemperature.鐵基粉末冶金材料的合金化可以通過幾種不同的途徑進行,其中有些是粉末冶金工藝所特有的。通過在鐵基粉末中加入不同含量的銅、鉬、鎳、鉻、錳、矽等元素,就可以得到不同性能表現的合金,合金元素的加入方式有預合金化粉末法、元素法等形式。具體採用哪種添加方法,取決於製品的性能要求,以及添加元素所形成氧化物在燒結溫度下的穩定性。

Chromium, manganese, and silicon form oxides that are relatively stable at the typical sintering temperature of 1120 ° C and are often used in the pre-alloyed form to minimize oxide formation. Oxides of copper, nickel, and molybdenum are more easily reduced at this temperature and are commonly used as particulate additives. It is important to remember that the additive must be diffused into austenite during sintering to be effective in enhancing most properties, especially harden-ability. If the additive in the compact is in the form of an unreduced oxide or a ‘free’ additive, no diffusion will occur during sintering and no property improvement will be realized from those particles. In fact, the presence of these particles could diminish the performance of the compact by creating hard or soft spots, degrading the quality of sintering or increasing the nonmetallic inclusion content.在鐵基零件的典型燒結溫度下(1120℃ ),鉻、錳、矽所生成的氧化物相當穩定,所以這些元素通常用預合金粉的形式加入,以避免氧化。銅、鎳、鉬的氧化物在燒結溫度下更容易被還原,它們通常就以元素粉的形式加入。需要強調的是,只有燒結時能擴散進入奧氏體內的元素,才能有效地提高合金性能,特別是淬硬性。如果壓結坯中的添加元素是以穩定氧化物的形式或游離單質的形式存在,在燒結過程中就不會產生擴散作用,因而也不能起到提高性能的作用。相反地 ,這些不溶顆粒的存在使合金中產生硬點或軟點,使材料的性能表現下降。

“It is important to remember that the additive must be diffused into austenite during sintering to be effective in enhancing most properties,especially harden-ability.”需要強調的是,只有燒結時能擴散進入奧氏體內的元素,才能有效地提高鐵合金性能,特別是淬硬性。

P2-Fig.1 Hybrid alloy using a pre-alloyed low-alloy steel base containing (wt%) 0.4 Mn, 1.25 Mo, & 1.4 Ni with 1

wt% elemental Cu + 0.7 wt% graphite additions (FLC-4805). Sintered at 1120° C without accelerated cooling (2

vol% Nital + 4 wt% Picral)圖1:混合的合金是使用預合金的低合金鋼為0.4wt% 錳、1.25wt% 鉬、1.4wt% 鎳、1wt% 元素銅與0.7wt% 石墨加入(FLC4805)。在1120° C 燒結後並無加速冷卻( 蝕刻液為2 vol% Nital + 4 wt% Picral )

2.1.1 Alloying methods 合金化的途徑

Three basic methods are used to distribute alloying additives in the base-powder particles or into the powder mixture, resulting in four alloy types. The alloying methods and powder types are:有三種不同的途徑可以將合金元素添加到基礎粉末或混合粉末中,由此形成四種合金類型:

・Admixed: a physical mixture of dry particulate additives in a base powder. The additives may be particles composed of a single element, more complex combinations of multiple elements, fine ferroalloys or easily reduced oxides that aremixed into the base powder元素法:在基礎粉末中物理混入添加元素粒子,添加元素粒子可以是單一元素,也可以是多種元素複合,或者是細的鐵合金粉,以及易還原的氧化物。

・Diffusion – or par tially-alloyed powder : elemental or oxide additive particles diffusion bonded to a base-powder surface using an annealing step.擴散法(部分預合金粉):單質或氧化物形式的添加元素通過高溫作用與基礎粉末之間形成擴散粘結。

・Prealloyed powder : desired elements are added to a molten metal bath before atomising. Prealloyed powders are uniform in chemical composition預合金粉:所需元素加入到熔融金屬中,再噴製成粉末,預合金粉能夠保證均勻的化學成份

・Hybrid alloy: an additional alloy type is the hybrid alloy which uses diffusion-alloyed or prealloyed-base powders with further alloying accomplished using admixing techniques.混合合金粉:用擴散粘結粉或預合金粉再進一步通過元素法混合添加元素

Of the four alloy types, only the pre-alloyed powder contains a homogeneous distribution of the alloying elements in each powder particle and, consequently, throughout a pressed and sintered part. Sintered parts made from the other three types contain micro-scale alloy gradients throughout the part volume. It is these gradients that result in local variations in the transformation products and determine the overall part properties.以上四種合金粉中,只有預合金粉可以保證每顆粉末粒子中都具有均勻的合金元素分佈,從而保證壓結坯和燒結產品中的合金元素分佈也是均勻的。其它三種合金粉都會在燒結產品的不同微區間產生成分差異,這種成分差異會導致不同微區裡的相變產物也存在差異,並決定製品的最終性能。■