■邱耀弘 博士

譯文提示//Hit of this translation

我們盡量按照原文,但因專有名詞的差異,翻譯將會調整或甚至補充文字,以使讀者充分理解文意。

We try to follow original text of this paper, but because of the differences in proper nouns, this translation will adjust or even supplement the text so that readers can fully understand the meaning of the text.本文翻譯有部分修改和前後次序的調動( 作者群往前),增加了部分以粗體字標示。英文部分略作美式英文的修正。並且盡量以不破壞原文的表格表示了部分圖形。 // This article has partial modifications and changes in the order (authors forward), Dr. Q add some legend part of blue text to indicate. Some of English section is slightly amended in American English. And try to represent part of the image in a table that does not break original text.

翻譯者//Translator

邱耀弘博士,25 年粉末成形技術專家,以金屬和陶瓷粉末注射為主。//Dr. Q (Yau Hung, Chiou),Dr. Q was an expert on powder forming technology on MIM and CIM (Metal-powder and Ceramic-powder injection molding) with 25 years experience.

联系方式:chiou_yh@yahoo.com.tw

Dr. Q 目前在中國和台灣均有超過10 家MIM 廠的輔導經驗,他也熟悉各種材料的加工技術。At present, there are more than 10 MIM factories in China and Taiwan of Dr.Q. He was familiar with various processing techniques of many materials also.

現職 // Present duty

中國廣東省東莞理工學院長安先進製造學院副教授 //Assistant professor of DGUT

台灣科技大學高速3D 列印中心兼任助理教授 //Assistant professor of TH3D of NTUST

中國粉末注射成形聯盟主席 //President of PIMA-CN (Powder Injection Molding Alliance – China)

Issue One: 問題一

Advanced manufacturing technologies, including 3-D printing, will disrupt how we manufacture. Are you ready to implement them? 包括3D 列印的先進製造技術來襲,將破壞我們的製造方式。您,準備好了嗎?

Authors// 作者群

Ben Sheppard is the leader of McKinsey & Company’s UK Product Development

Practice// 班.席派瑞德先生是麥肯錫公司英國的產品開發實踐部的領導

聯繫方式:Benedict_Sheppard@mckinsey.comBen is a chartered engineer, with a passion for helping clients sustainably improve their performance. He has worked with over 30 of the world’s preeminent manufacturing companies, leading major design improvement programs on everything from jet engines to cans of baked beans. He founded McKinsey’s Designto Value laboratory in London. Before joining McKinsey, Ben designed and built the world’scheapest deep-sea camera. //Ben 是一名特許工程師,熱衷於為客戶提供持續改進方案幫助客戶提升。他與世界上30 強的製造業公司合作,在從噴氣發動機到烘焙豆罐頭等方面進行重大的設計改進。他創辦了麥肯錫在倫敦設計的價值實驗室,在加入麥肯錫之前,Ben 曾設計並建造了世界上最便宜的深海相機。

Colin Shaw is the leader of McKinsey & Company’s UK Operations Practice//

柯林.蕭先生是麥肯錫公司英國的業務實踐部的領導

聯繫方式:Colin_Shaw-PRI@mckinsey.comColin is an Expert Principal, based in the London office. He works purely on projects that transform the operational performance and cost of his clients. He covers topics such as lean manufacturing, maintenance and reliability, supply chain management, procurement and back-office optimization.Prior to McKinsey, Colin worked at British Airways on a variety of aircraft performance improvement projects before being involved in resolving technical problems associated with the Concorde aircraft, enabling the aircraft to enter back into service. // Colin 是一位專家,工作於麥肯錫總部設在倫敦辦事處。他純粹致力於改變客戶的經營業績和成本的項目,涵蓋了精益生產、維護可靠性、供應鏈管理、採購和後台優化等主題。在麥肯錫之前,Colin 在參與解決協和飛機相關技術問題之前,在英國航空公司進行了各種飛機性能改進專案的工作,使飛機重新投入使用。

Barry Williams is an Expert in McKinsey & Company’s Manufacturing Practice //

貝利.威廉先生是麥肯錫公司的生產實踐專家。

聯繫方式:Barry_Williams@mckinsey.com

Barry is a former Senior Vice President of Manufacturing at Rolls-Royce and has also held senior leadership positions at BAE Systems and Airbus. As a consultant, he has led diagnostic and transformation activities on everything from latex manufacturing to the production of luxury cars. He was first coached in process improvement by the Japan Institute of Plant Maintenance and later directed his MBA studies to specialize in world-class manufacturing techniques. //Barry 是勞斯萊斯製造業的前高級副總裁,並在BAE 系統公司和空客公司擔任高級領導職務。作為一名顧問,他領導了從乳膠製造到豪華轎車生產的一切診斷和轉化活動。他最初是由日本植物維修研究所指導工藝改進的,後來他執導了MBA 的研究,專門研究世界級的製造技術。

John Persaud is a Specialist in McKinsey & Company’s Manufacturing Practice

// 約翰.波紹是麥肯錫公司製造業的專家。

聯繫方式:John_Persaud@mckinsey.comJohn is a lean manufacturing specialist who delivers sustainable change through individual and organizational capability building. He has worked across multiple high-technology and high-volume industries, including aerospace, defense, pharmaceuticals, and consumer goods. Before McKinsey, John was an operation leader in pulp and paper manufacturing. //John 是一個精益生產專家,通過個人和組織能力建設提供可持續的變化改進。他曾在多個高科技和高容量的工業領域工作過,包括航空航太、國防、製藥和消費品。進入麥肯錫公司之前,John 是製漿造紙行業的運營領導者。

Jörg Bromberger is a Senior Practice Manager in McKinsey & Company’s EMEA

Manufacturing Practice //約格•布魯姆伯格是麥肯錫公司EMEA 製造實踐的高級實踐經理。

聯繫方式:Joerg_Bromberger@mckinsey.comJörg is coleading McKinsey’s initiatives in advanced manufacturing technologies with particular focus on 3-D printing and digital manufacturing technologies. He has been serving several clients – both large OEMs and government institutions – in shaping their manufacturing strategies, developing new business models, and setting up competence centers for new technologies. // Jörg 正在梳理麥肯錫在先進製造技術方面的舉措,特別關注3D 列印和數位製造技術。他一直在為幾個客戶 – 大型OEM 和政府機構服務 – 在塑造他們的製造戰略,開發新的商業模式,以及建立新技術的能力中心。

Contents // 内容

- Executive summary // 摘要

- Introduction: the shape of things to come //簡介:給予物件的形狀

- 1.The advanced manufacturing technology landscape// 先進製造技術的景觀

- 2.Top technologies: additive manufacturing (AM) and metal injection molding (MIM) // 頂尖技術:增材(AM) 與金屬注射成形(MIM)

- 3.Managing and implementing new technologies//新技術的管理和實施*图像是微阵列结构,只可能采用3D 打印技術來實現的一種輕質結構體

Executive summary // 摘要

Manufacturing is going through one of its greatest periods of change since the Second World War. The manufacturing technologies used to shape, join, finish, and measure components are changing dramatically after decades of more incremental evolution.// 製造業正經歷二戰以後幾項最偉大的變革時期之一,用於造型、連接、完成和測量元件的製造技術,在數十年的漸進式進化之後正在發生巨大的變化。

The landscape of these advanced technologies is rapidly shifting and poorly mapped. Through a process of extensive interviews with manufacturing managers and experts, we have compiled a list of the 25 technologies with the most potential for impact this decade. Of these, additive manufacturing (AM, commonly referred to as 3-D printing) and metal injection molding (MIM) have the broadest potential for cross-industry disruption. Metal injection molding is ready for widespread adoption now, while the tipping point for additive manufacturing for the majority of companies is still five to ten years away for full-scale production. // 這些先進技術的景觀正在迅速轉變和拙劣地被映射出來,通過對製造業的經理和專家的廣泛訪談,我們編制了25 項最具潛力的技術清單。其中,增材製造(AM,通常稱為3-D 列印)和金屬注射成形(MIM)具有跨行業中斷的最廣泛的潛力。其中金屬注射成形更是已準備好並被廣泛採用,而為多數公司青睞的增材製造,其引爆點仍然是五至十年以後的大規模生產。

Exhibit 1. Similarity between shop floors in manufacturing value chains in the 1960s and 2000s. Left: 1962

Exhibit 1. Similarity between shop floors in manufacturing value chains in the 1960s and 2000s. Left: 1962

Image courtesy of Eastside Community Heritage; Right: 2014 Image courtesy of Turnxon Precision LTD //

展示1 比較1960 和2000 年兩個時代具有製造業價值鏈的車間層的相似性。

圖左:1962 年的Eastside Community Heritage 工廠樓層,許多車床排列一起,每台機器有一位工人操作;

圖右:2014 年的Turnxon Precision LTD 工廠也是一樣的景象SOURCE: http://www.hidden-histories.org.uk; http://www.turnxon.com // 圖片來源

Choosing to implement one of these new technologies is no small undertaking: the cost of a poor transition can wipe out the potential savings and cause production delays. Less than 10% of companies today possess a robust capability for moving rapidly from a manufacturing strategy through technological identification and prioritization to implementation. However, those who succeed have a competitive advantage through increased flexibility, reduced costs, and a shorter time to market. //選擇實施這些新技術中的任一項,都是不小的事情:當實施後的一個糟糕的過渡成本可以消耗公司現有的積蓄並導致生產延遲。目前,不到10% 的公司擁有強大的能力,通過技術鑑定優先化到真正實施,迅速的從製造戰略轉移到量產。然而,成功的人可以通過增加靈活性、降低成本和縮短市場時間來獲得競爭優勢。

Introduction: the shape of things to come // 簡介:給予物件的形狀

If you visited a manufacturing shop floor in the 1960s, you would have seen a small army of technicians working on lathes, milling machines, presses, and casting equipment. Jump forward half a century, and what has changed? Hopefully, the value stream is leaner with less waste, there are visual management processes in place, inventory and order management are slicker, and a degree of automation has been introduced. However, the machines themselves are still recognizable from their 1960s predecessors. They have evolved and improved but, in many cases, are still based on the same twentieth century principles(Exhibit 1). //如果你在20 世紀的60 年代參觀了一家製造車間,你會看到一小部分技術工人在車床、銑床、壓制機和鑄造設備上工作。再往前邁進半個世紀,又看到發生了什麼變化?希望,流水線生使得浪費變得越少,視覺化管理過程就位,庫存和訂單管理也越靈活,自動化程度也就越高。然而,機器本身仍然可以從20 世紀60 年代的前輩鄉比較出來,已經被發明和改進了,但在許多情況下,設備仍然是基於二十世紀的原則而相似( 展示1)

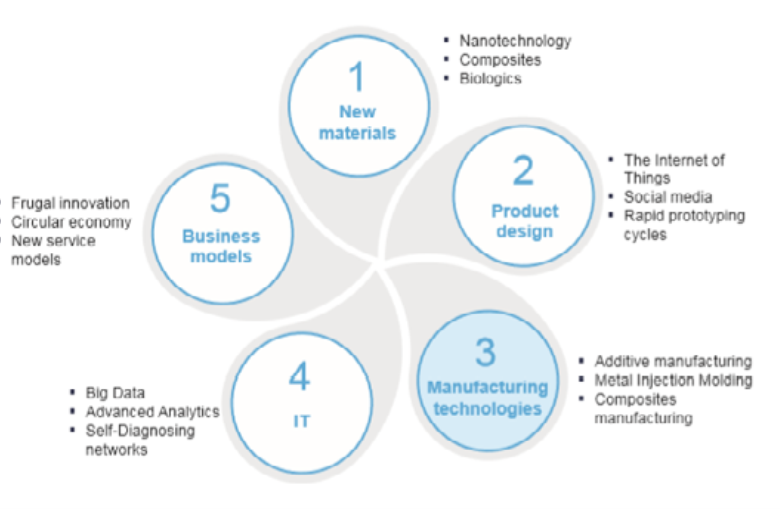

That may be about to change. McKinsey has identified accelerated development across a broad range of manufacturing areas in the past three to five years: materials, product design, manufacturing technologies,IT, and business models (Exhibit 2). // 但接下來,這種情況可能會改變。麥肯錫在過去的三到五年中,識別出了在製造業領域的加速發展的五大要素,如上圖展示2 的說明:

(1) 新材料(New material):

- Nano technology // 奈米技術

- Composites // 複合材料

- Biologics // 生醫材料

(2) 產品設計(Product design)

- The Internet of Things // 物聯網

- Social media // 社交媒體

- Rapid prototyping cycles // 快速原型製造循環

(3) 製造技術(Manufacture technologies)

- Additive manufacturing // 增材製造

- Metal Injection Molding // 金屬注射成形

- Composites manufacturing // 複合製造

(4) 情報技術(Information technology)

- Big Data // 大數據

- Advanced Analytics // 高等分析

- Self-Diagnosing networks // 自我診斷網路

(5) 商業模式(Business models)

- Frugal innovation // 節儉創新

- Circular economy // 循環經濟

- New service models // 新服務模式

This paper focuses on advanced manufacturing technologies. Additive manufacturing has put this field into the limelight, and over the past 12 months, McKinsey has received more questions from COOs and manufacturing executives about advanced manufacturing than about any other of the fiveareas mentioned above. / /本文主要研究先進製造技術,而增材製造使這一領域成為眾人矚目的焦點,在過去的12 個月中,麥肯錫收到了來自COOS 和製造業高管的關於先進製造業的更多問題,而且不屬於上述五個領域中的任何其他問題。

更多完整內容將在專題後(P56-79),不要錯過囉。■

※ 此篇原文報導出處為麥肯錫顧問公司文章『https://www.mckinsey.com/~/media/mckinsey/our%20people/ben%20sheppard/factor y%20of % 2 0 t h e % 2 0 f u t u re % 2 0 – % 2 0 a d va n c e d % 2 0manufacturing%20technologies.ashx』