■邱耀弘博士

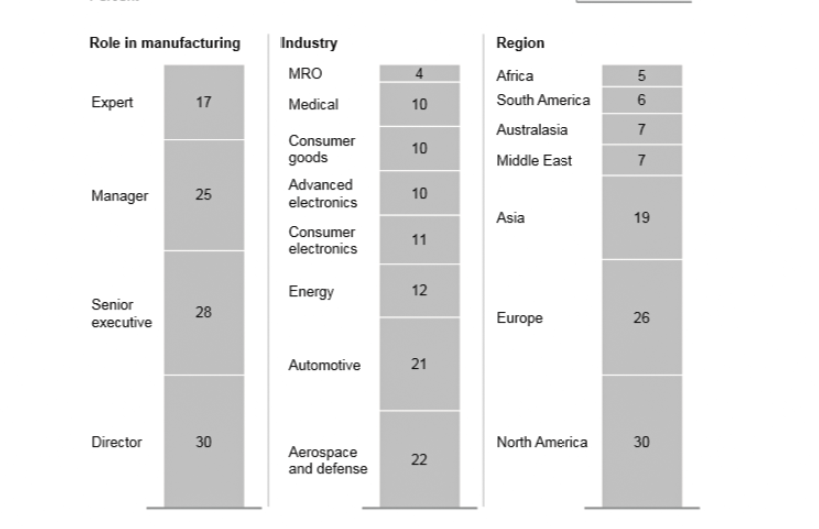

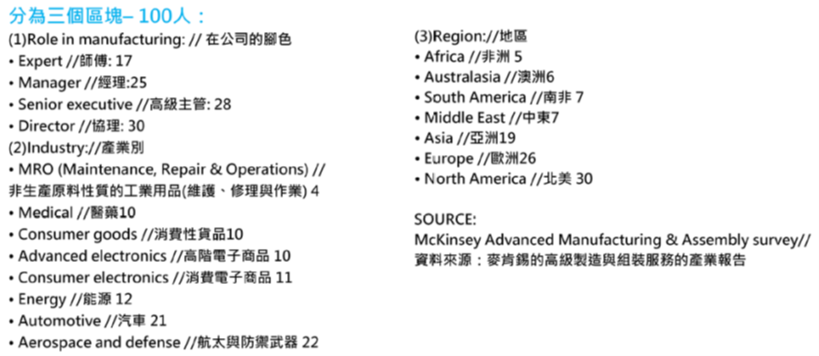

Advanced manufacturing technology is a notoriously difficult field to track and manage. Technologies are constantly evolving and emerging. Technical operational data for new equipment is scant and not readily comparable across suppliers. Descriptions of maturity, cost, and readiness for adoption are sometimes skewed by suppliers and media. In order to develop a robust and independent perspective on which technologies matter the most, we have interviewed and surveyed over 100 top manufacturing leaders from broad geographic and industrial backgrounds (Exhibit 3).先進製造技術是一個眾所周知的難以跟踪和管理的領域,技術在不斷地發展和湧現。新設備的技術運行資料很少,而且不容易在供應商之間進行比較。成熟度、成本和準備就緒的描述有時被供應商和媒體歪曲,為了開發一個強大和獨立的角度,其中最重要的技術,我們採訪和調查了100 個頂級製造業領導者從廣闊的地理和工業背景( 展示3)

Exhibit 3. Background of survey and interview respondents. // 展示3. 被調查與訪談者的背景統計。

Exhibit 3. Background of survey and interview respondents. // 展示3. 被調查與訪談者的背景統計。

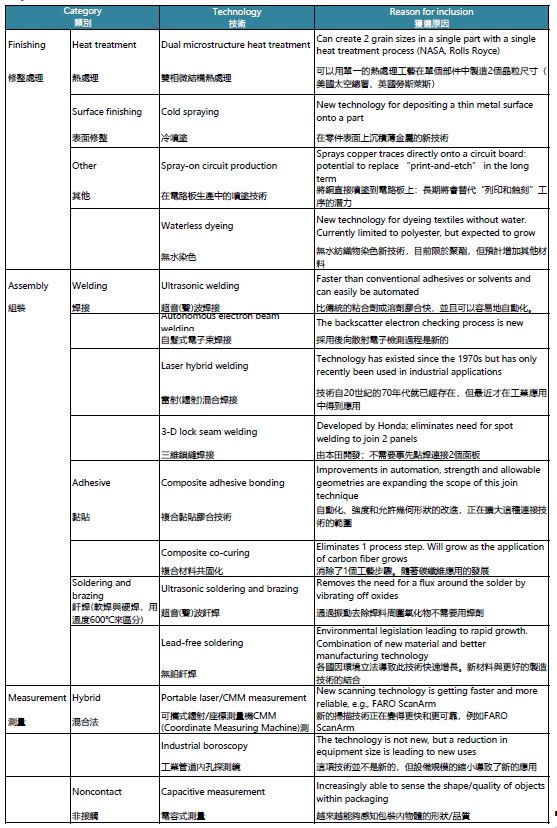

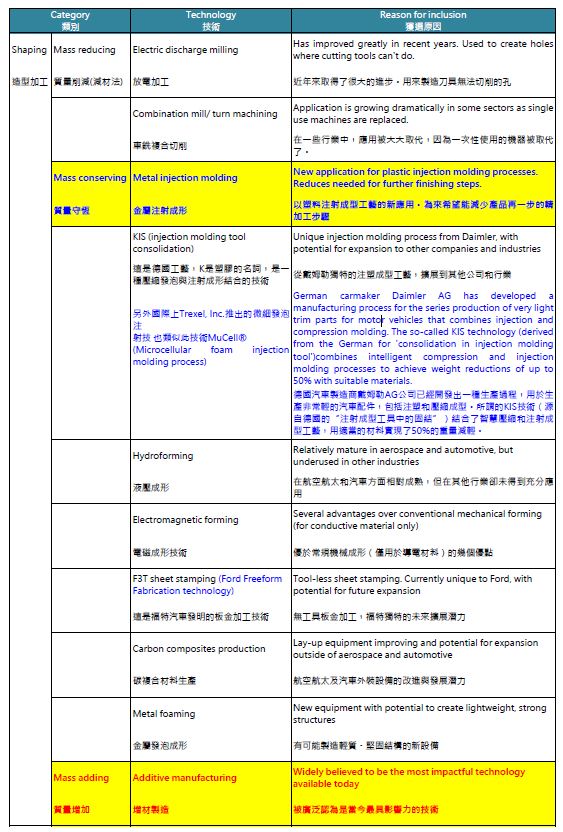

We identified 25 technologies to watch. These are either fundamentally new or have recently gone through a cycle of such improvement that they offer performance in a different league compared to previous-generation equipment. Benefits include reduced tooling cost, improved precision, faster production time, and greater flexibility (Exhibit 4). //我們確定了25 種技術值得關注。這些要么根本上是新的,要么是最近經歷了這樣一個改進週期,與前一代設備相比,它們在不同的聯盟中提供了性能。效益包括降低模具成本、提高精度、更快的生產時間和更大的靈活性( 見展示4)。

This broad collection of technologies spans shaping, joining, finishing, and measurement. It ranges from the widely documented field of additive manufacturing to the lesser known F3T sheet stamping process, invented by Ford, which allows sheets to be stamped without the need for tooling. //這些廣泛的技術跨越了成形,連接,整理和測量。它的範圍從廣泛記錄的添加劑製造領域到較不知名的如F3T(Ford Freeform Fabrication technology) 板材沖壓工藝,由福特公司發明,它允許在不需要模具的情況下沖壓板材。

SOURCE: McKinsey Operations Practice, expert interviews; McKinsey Advanced Manufacturing & Assembly survey// 資料來源:麥肯錫操作實踐,專家訪談;麥肯錫先進製造和裝配調查報告

SOURCE: McKinsey Operations Practice, expert interviews; McKinsey Advanced Manufacturing & Assembly survey// 資料來源:麥肯錫操作實踐,專家訪談;麥肯錫先進製造和裝配調查報告