■邱耀弘 博士

Taking technologies like additive manufacturing and metal injection molding from concept to full implementation on the shop floor is a daunting task for many companies. The cost of prolonged line stoppage from a poor transition can outweigh the potential cost savings, and building the required talent and processes are not trivial tasks. //在生產車間,採用附加製造和金屬注射成型等技術,從概念到全面實施,對許多公司來說是一項艱鉅的任務。從一個糟糕的過渡期延長的停工成本可以超過潛在的成本節約,並且建立所需的人才和過程不是微不足道的任務。

However, as the cycle of technological change accelerates, having the organizational capability to rapidly identify, prioritize, and implement new manufacturing technologies is quickly becoming a fundamental requirement. Companies that can implement new technology quickly and effectively will have a competitive advantage through increased flexibility, reduced cost, and a shorter time to market. //然而,隨著技術變革週期的加快,具有快速識別、優先化和實施新製造技術的組織能力正在迅速成為一個基本要求。能夠快速有效地實施新技術的公司將通過增加靈活性、降低成本和更短的上市時間而具有競爭優勢。

In our experience, companies that are succeeding on this front have talented people and formal processes in place along all four key steps to execution: //在我們的經驗中,在這方面取得成功的公司在執行的四個關鍵步驟中都有人才和正式流程:

3.1 Strategy // 戰略

A clear manufacturing strategy tied to business strategy. Leading companies quantify the relative importance of lead times, quality, flexibility, and cost for various customer segments and translate them into a prioritized set of strategic manufacturing goals. This allows strategic Capex decisions to be made on investments into new technologies, and where in the manufacturing footprint they should be deployed.The best manufacturing strategies also make it clear when investments are not going to be made. This prevents projects idling in the shadows and consuming valuable resources, allowing the business to refocus its efforts on other improvement levers such as process optimization. //一個明確的製造戰略與商業戰略掛鉤。領先的公司量化了不同客戶細分的交貨期、品質、靈活性和成本的相對重要性,並將它們轉化為戰略製造目標的優先次序。這使得戰略CAPEX 決策可以對新技術進行投資,並在製造業的足跡中進行部署。最好的製造策略也清楚地說明了當投資將不被製造的時候。這樣可以防止專案在陰影中閒置,並消耗寶貴的資源,從而使業務重新集中精力於其他改進槓桿,如過程優化。

We often see companies struggling to quickly and effectively make these strategic decisions. Typically there are two root causes of the problem. Firstly, that the senior leadership does not have access to the right level of quantified insight into what the business needs and what different options will cost to deliver it. This requires both an investment in the organization’s analytical capability as well as in data acquisition and management. Secondly, and more commonly, there is disconnect between the strategies and incentives of different departments, such as manufacturing, R&D, and supply chain. It is important for senior management to take the lead in aligning the departments’ incentives and metrics: this cannot be left solely to finance and HR. It also requires active risk management and regular feedback loops between the departments. This ensures that corrections are made to their respective strategies, and that they stayaligned. //我們經常看到公司努力快速有效地做出這些戰略決策。通常問題的根源有兩個。首先,高級領導層無法獲得對業務需要的量化洞察力的正確水準,以及不同的選擇會付出多少代價。這既需要對組織的分析能力的投資,也需要對資料的採集和管理。其次,更常見的是,不同部門之間的戰略和激勵,如製造業、研發和供應鏈之間存在脫節。重要的是,高級管理人員要率先調整部門的激勵和指標:這不能僅僅局限於財務和人力資源。它還需要積極的風險管理和部門之間的定期反饋迴路。這確保了對各自策略的更正,並且保持對齊。

3.2 Technology identification // 技術鑑定

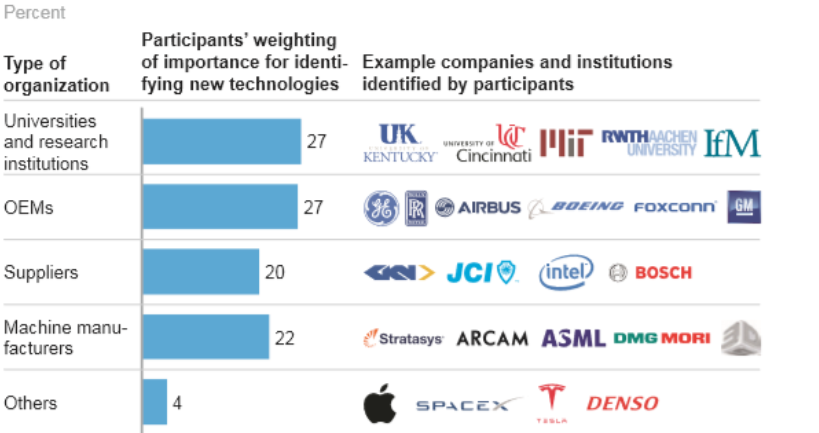

There are strong internal and external networks for identifying relevant new technologies. We asked at over 80 leading companies who they work with to stay abreast of technological advances in manufacturing. Household names like MIT, GE, and Intel came up frequently. However, the companies with the best track record for technological implementation had a wider network of advisors and included “wild-card” organizations like the Disney Institute to join their meetings and think through the operatorexperience of new machinery. //

有強大的內部和外部網路來識別相關的新技術。我們要求超過80 家主要公司的高管們跟上製造業的技術進步。像麻省理工、通用電氣和英特爾這樣的家喻戶曉的名字頻頻出現。然而,具有最好的技術實現記錄的公司擁有更廣泛的顧問網路,並包括“迪士尼”研究所的“萬用字元”組織來參加他們的會議,並通過運營商的新機器的經驗來思考。

Too often, networks look excellent on paper, but the full potential of the industry, government bodies, and academic institutions working together is not exploited. Getting your network to work for you requiresna clear framework as well as setting out the responsibilities of each partner and the benefits they will each receive. The performance of the network should be managed compared to a set of quantifiedinput nand output metrics. The breadth of the network is also important: bringing in parties with expertise in technological adoption on the front line may be as important as learning about the next best thing in composite adhesive joining. The network’s search should be tied back to the manufacturing strategy toavoid “boiling the ocean” (Exhibit 11) //很多時候,網路在紙上看起來很好,但是工業、政府機構和學術機構共同工作的全部潛力沒有被利用。讓你的網路為你工作需要一個明確的框架,並規定每個合夥人的責任和他們將得到的好處。與一組量化的輸入和輸出度量相比,網路的性能應該被管理。網路的廣度也是很重要的:在前線引進技術方面的專門知識可能和學習複合粘合劑連接中的下一個問題一樣重要。為了避免” 沸騰的海洋”,網路搜索應該與製造戰略掛鉤(如展示11)

Exhibit 11. Leading institutions highlighted by survey results// 展示11. 調查結果突出的主要機構

Exhibit 11. Leading institutions highlighted by survey results// 展示11. 調查結果突出的主要機構

圖示說明

● Type of organization // 組織的類型

● Universities and research institutions // 大學與研究機構

● OEMs // 代工廠

● Suppliers // 供應商( 粉末、晶片等)

● Machine manufacturers // 設備製造商

● Others // 其他

● Participants’ weighting of importance for identifying new technologies //

參與者對確定新技術的重要性的重視程度 ( 以百分比表示)

● Example companies and institutions identified by participants //

參與者所確定的公司和機構的幾個例子( 以商標表示)

● SOURCE: McKinsey Advanced Manufacturing & Assembly survey, n=100//

資料來源:麥肯錫先進製造與組裝調查報告,受訪公司總數 = 100

SOURCE: McKinsey Advanced Manufacturing & Assembly survey//

資料來源:麥肯錫先進製造與組裝調查報告

3.3Technology prioritization // 技術優先化

A robust set of processes to quantify the total cost and relative merits of each technology compared to the business strategy. A common pitfall is to have a multi-stage-gated process where the answer is always “yes” at each stage. The process needs strong executives with the courage to pilot risky new technologies and even more courage to kill projects with high sunk costs before they do more damage.The executives need to be supported by analysts with the specialist skill set required to forecast the impactover time of transitioning to a technology. Many companies today still do this on an informal basis, even inthe aerospace and defense sector. //一組穩健的過程來量化每項技術的總成本和相對優點,與業務策略相比較。一個常見的陷阱是有一個多級門控過程,在每個階段答案總是“是”。這一過程需要強有力的管理人員,敢於冒險嘗試新的技術,甚至更大膽地在高傷害成本下殺死高成本的項目。管理人員需要得到分析師的支援,專家技能集需要預測過渡到技術的時間的影響。許多公司今天仍然在非正式的基礎上,甚至在航空航太和國防部門。

3.4 Implementation // 實施

A rapid approach to piloting and rolling out new technologies. The fear of disruption caused by a change in manufacturing technology can often paralyze the implementation process. Several of the companies we interviewed had maintained their existing manufacturing technologies despite having known for two to threeyears that a better alternative exists. //一種快速引導和推出新技術的方法。由於製造技術的改變而引起的混亂的恐懼常常會使實施過程癱瘓。我們採訪的幾個公司保持了他們現有的製造技術,儘管已經知道了兩到三年,一個更好的替代品存在。

There are very few manufacturing managers who can truly balance the day-to-day pressure of meeting operational targets with the creativity and openness needed for the implementation of new technology. Creating a small implementation SWAT team can be a way to address this issue. A high-performing team with tight 19Factory of the Future timelines, concrete goals, a small but liquid budget and freedom from red tape can achieve rapid results and break the paralysis. Some companies have created mock manufacturing environments to test changes in a nondisruptive way and found the cost of the sites was outweighed by the overall acceleration and improved quality of the rollout. //很少有製造業管理者能夠真正平衡日常經營目標的壓力和實施新技術所需的創造力和開放性。創建一個小型的SWAT 團隊是解決這個問題的一種方式。一個高績效的團隊,在未來的時間表,具體的目標,一個小而流暢的預算和免於繁文縟節的19 工廠,可以實現快速的結果,打破癱瘓。一些公司已經創建了類比製造環境來測試非破壞性的變化,發現網站的成本被整體加速和改進的推出品質所壓垮。

It is important to make sure that the implementation project team’s incentives are aligned with the operational manager’s incentives. The team’s metrics need to encourage long-term benefits over short term disruption. The quality and crossfunctional nature of the implementation team are also critical: it must contain people with skills in communication, training, technical transition, and change management. //重要的是要確保執行專案團隊的激勵與運營經理的激勵相一致。該團隊的指標需要鼓勵短期利益的長期影響。實施團隊的品質和跨職能性質也是至關重要的:它必須包含有溝通、培訓、技術過渡和變革管理技能的人員。

We interviewed manufacturing leaders from over 80 companies to understand how they performed at each of the four stages. Overall, managing manufacturing technology was acknowledged as an area that has not received sufficient corporate attention. However, as lean and Six Sigma programs increasingly struggle to find more waste to remove from the process, the equipment itself is rapidly becoming the next frontier for major improvement. //

我們採訪了來自80 多家公司的製造業領導者,以了解他們在四個階段中的每一個階段的表現。總體而言,管理製造技術被公認為一個沒有得到足夠的企業關注的領域。然而,隨著精益生產和六西格瑪項目越來越難以找到更多的廢物從過程中去除,設備本身正在迅速成為下一個主要改進的前沿。

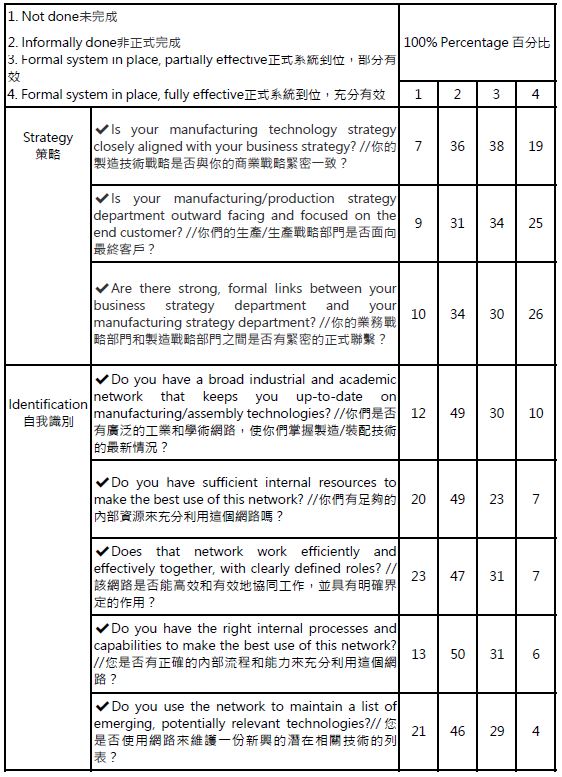

Only 20% of companies surveyed felt that their manufacturing strategies were fully effective and aligned with their business strategies. Less than 10% believed that they had fully effective networks and processes for identifying new technologies. Furthermore, less than 10% felt that technologies identified were analyzed as thoroughly as they should be. And finally, less than 10% felt the implementation processes were quick and effective. Obviously, this is an area ripe for improvement (Exhibit 12). //只有20% 的被調查公司認為他們的製造戰略是完全有效的,並與他們的商業戰略相一致。不到10% 的人相信他們有完全有效的網路和過程來識別新技術。此外,不到10% 的人認為所識別的技術被徹底地分析了。最後,不到10% 的人感覺到實施過程是快速有效的。顯然,這是一個成熟的領域(12)。

SOURCE: McKinsey Advanced Manufacturing & Assembly survey// 資料來源:麥肯錫先進製造與組裝調查報告Exhibit 12. Survey results on moving from strategy to implementation // 展示12. 從戰略走向實施的調查結果

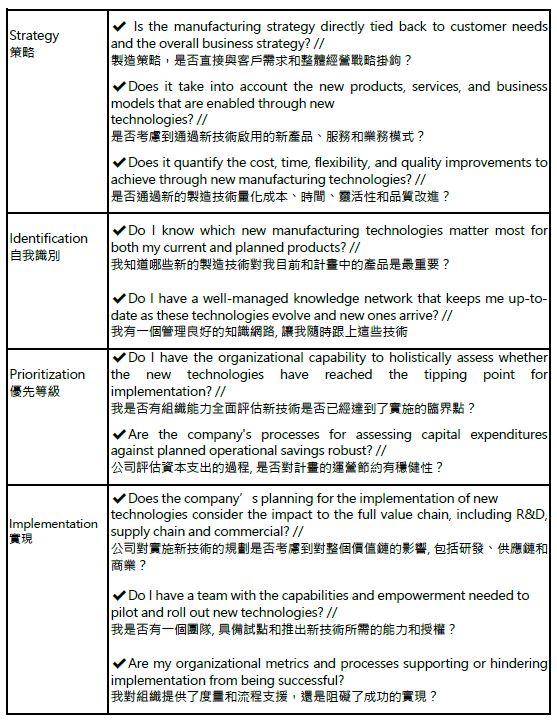

Exhibit 13. Top ten questions for executives on advanced manufacturing technologies //高級製造技術主管的十個問題

Those companies that are building the capabilities to “refresh their shop floor” quickly and seamlessly have a competitive advantage through reduced cost, improved quality, increased flexibility, and faster timen to market. Therefore, now is the ideal time for manufacturing executives to ask themselves challenging questions about their own manufacturing technology (Exhibit 13). //通過降低成本、提高品質、增加靈活性和更快的上市時間,那些正在建立快速“無縫更新”能力的公司具有競爭優勢。因此,現在是製造管理者問自己關於他們自己的製造技術的挑戰性問題的理想時間(展示13)。

The answers to these questions vary by company, industry, and region. However, as the pace of technological change continues to accelerate, not having answers to these questions is no longer an option. We do not know what the manufacturing shop floor of 2020 will look like, but we do know that companies cannot afford for it to look the same as it does today. //這些問題的答案因公司、行業和地區而不同。然而,隨著技術變革的步伐不斷加快,沒有對這些問題的回答不再是一種選擇。我們不知道2020 的製造車間會是什麼樣子,但我們確實知道,公司負擔不起它看起來像今天一樣。■

※ 此篇原文報導出處為麥肯錫顧問公司文章

『https://www.mckinsey.com/~/media/mckinsey/our%20people/ben%20sheppard/factory%20of%20the%20future%20-%20advanced%20manufacturing%20technologies.ashx』