■ Compiled by Jessy Lu

榮獲2018SPE 技術賦能獎

第18 屆SPE 汽車創新獎2018 年6 月6 日在德國諾伊斯市舉行了頒獎典禮。組委會新設了三個獎項,即底盤單元獎、結構部件獎以及技術賦能獎。在“技術賦能獎”的評選中,創新塑料改性專家安科羅塑料(AKROPLASTIC)憑藉其開發的“剪切試樣”驗證機部件獲得二等獎。該成果代表了金屬/ 塑料複合材料技術的重大進步,並且創造了新型粘合增強複合物。

At this year‵s SPE awards, which were presented in Neuss on 6 July, 2018, for the 18th time, three new categories were added: Chassis Unit, Structural Components and Enabler Technology. In the Enabler Technology category, AKRO-PLASTIC, a specialist in innovative plastic compounds, took second place for its “shear test specimen” demonstrator component, which represents significant developments in metal/ pla2019stic composite technology and the creation ofadhesion-optimized compounds.

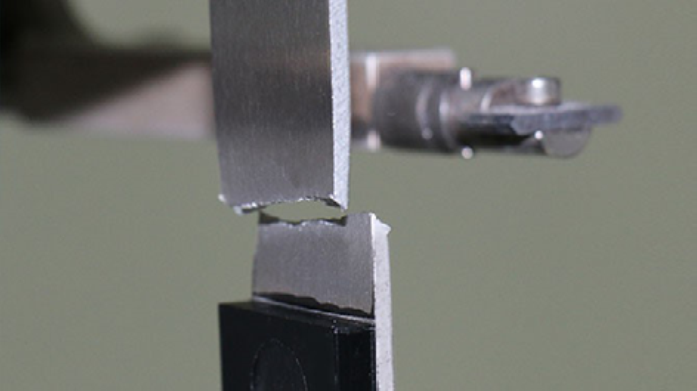

新獎項“技術賦能獎”的設立是為了介紹和推廣新興的生產技術和自動化生產工藝。評委會對安科羅塑料公司與Plasmatreat 公司合作開發的用於生產可靠並具備優異的金屬/ 塑料粘合強度的PST 工藝技術(Plasma- SealTight®)印象深刻。該技術創新性地採用了在線噴塗工藝:在第一步用Openair 等離子體清潔金屬嵌件表面,然後在第二步用等離子噴嘴噴塗預聚前體在金屬表面形成聚合。運用該技術,塑料和金屬之間粘合層的拉伸剪切強度可以高達50Mpa 以上。該項目的研發團隊已經進行了多次AKROMID®B3GF 30 7 PST 材料(30% 玻纖增強的粘合強化聚酰胺6)與鋁材的粘合強度測試,並成功消除了塑料和金屬粘接界面斷裂的現象。

The purpose of the “Enabler Technology”category is to introduce and explain new production te c h n i q u e s a n d a u to m a te d m a n u f a c t u r i n gprocesses. The jury was very impressed with the PST process technology (Plasma-SealTight®) developed by AKRO-PLASTIC in collaboration with Plasmatreat to produce reliable and excellent metal/plastic bond strengths. A special feature of this technique is the implementation of an inline process for the first time. In the first step, the surface of the metal insert is cleaned with Openair plasma. In steptwo, a second plasma nozzle applies a chemical bonding agent which polymerizes on the metal surface. This technology produces tensile shear strengths between the plastic and metal of more than 50 MPa. In current tests investigating the bond strength between aluminum and AKROMID® B3 GF 30 7 PST (adhesion-optimized polyamide 6 GF 30), the development team succeeded in preventing the break failure in the interface between the plastic and the metal.

使用創新PST 工藝噴塗形成的粘接聚合物可與金屬(銅、鋁、鋼或不銹鋼)表面粘接,並同時生成可與AKROMID®B3GF 30 7 PST 材料粘接的有機化合物。在噴塗該聚合物時同時將金屬 嵌件加熱至粘結聚合物的熔點以上,就可激活粘接效應。試驗試樣的金屬/塑料粘合強度測試值在鋁材(而非粘結層)因荷載過高而發生斷裂前達到了35MPa(見圖1)。

The layer that is applied with the innovative PST process bonds with the metal surface (copper,aluminum, steel or stainless steel) and, at the same time, generates organic compounds that allow bonding with the AKROMID® B3 GF 30 7 PST material. In order to activate this bonding, the metal insert is heated to a temperature above the melting point of the polymer when the polymer is applied. The metal/plastic bond of the test specimen demonstrates a strength of 35 MPa before the aluminum, and not the adhesive bond, fails due to the extreme loading.

"即便在120° C 高溫下,該材料對金屬/ 塑料的粘合強度也高達20 MPa 以上,所以非常適用於承重部件或者那些需要防止介質滲漏的金屬嵌件成型加工中。"

“The metal/plastic bond strength reaches strengths of more than 20 MPa even at 120 ℃ and is therefore suitable for load-bearing components as well as for media-impermeable overmoulding of metal inserts.” ■

安科羅塑料公司應用工程主管-Cyprian Golebiewski Cyprian Golebiewski, Head of Application Engineering at AKRO-PLASTIC

編譯者:Jessy Lu

Email:jessy.lu@kdf-asia.com