■ Compiled by Jessy Lu

安科羅工程塑料公司

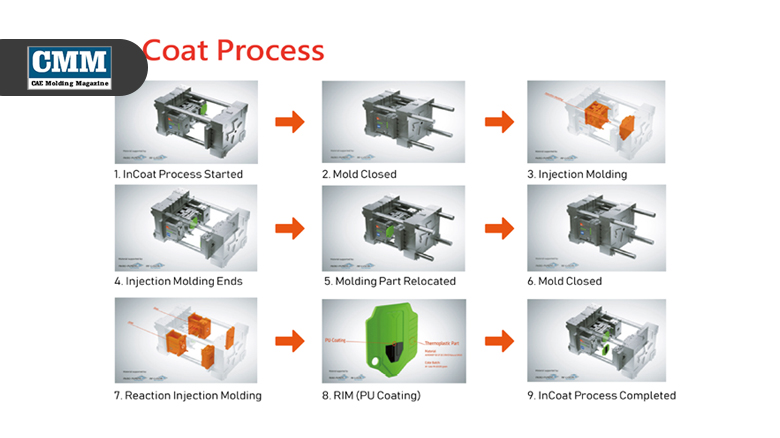

與其姊妹公司AF-COLOR合作支援內層包覆射出成型 技術(InCoat Process),以單一加工成型步驟成功生產 一個內層包覆PU的低吸濕PA6+20%玻璃纖維材質的 引擎蓋。這個稱為內層包覆射出成型(InCoat Process) 的創新技術結合了熱可塑性塑料的射出成型與PU的反 應射出成型 (Reaction Injection Molding,簡稱 RIM), 其中的關鍵是所使用的PA原料必須與PU產生好的黏 著性。為了實現這個目的,安科羅工程塑料公司提供了 AKROMID® B3 GF 20 2 RM-D natural,而AF-COLOR 則開發了適合這個規格適用的綠色色母。 AKRO-PLASTIC and its sister company AFCOLOR supported the InCoat process in which a demonstration engine cover part was overflooded with a PU layer in a single process step. Here one of the prerequisites was a material to which PU would have a good bonding. AKRO PLASTIC supported with the material AKROMID® B3 GF 20 2 RM-D natural (4164) and AF-COLOR developed a green colour masterbatch AF-Color® PA 601292 green suitable for this grade.

目前的汽車用內裝設計的趨勢已經轉為特別要求輕量化 與高品質的表面特性,這是符合經濟與大量生產的解決方案。

The trend towards light and high-quality surfaces, which are particularly in demand in the automotive industry for the design of vehicle interiors, is fueling the demand for economical and mass-produced solutions.

這些典型的汽車用內裝應用包含儀表板,汽車門板, 柱飾與其他裝飾部件,藉著合併PA複合材料與PU 材料的成型,高附加價值的部件可以有效的被大量生 產.因此這項新技術不只可以使用於汽車內裝應用也 可使用於汽車外裝應用,更可以擴展於其他需要這項 特殊成型方式的工業產品。

Typical applications in automotive interior are instrument panels, door panels, pillar trims and other trim components. By combining injection molding with the PU process, higher-value components can be effectively produced in large quantities. This makes this technology interesting not only for a variety of applications in the automotive interior, but also in the automotive exteriors. This solution could also be interesting for other industries where injection moulded parts have a much broader application.■

參與專案的合作夥伴:

東莞伊之密精密機械股份有限公司: yizumi.com GK Concept GmbH: gkconcept.de/en/ Frimo Group GmbH: frimo.com