■耀德講堂/ 邱耀弘 博士

專家評論

3D 列印是否真的能快速改變我們的生活,其實要看我們有沒有真的接觸到它們的產品,若只是列印公仔療癒人心,那對工業進展就毫無幫助。所幸3D 產業的業者們不斷改進,ExOne 的直接黏結劑噴射法是當今3D 列印能夠製作最多最廣泛的材料的列印設備,目前連HP、Digital Metal 等等知名大牌都沒有辦法超越,我們來看看2020 年ExOne 又在列印材料進展到什麼範圍!翻譯中如有不甚了解請對照原文,並歡迎討論!藍字為譯者的自行補充說明。

本文開始

Pe r s p e c t i v e o n E x O n e’s Me t a l Ma t e r i a l s Announcement A Message from John F. Hartner, Chief Executive Officer of The ExOne Company February 25, 2020.

ExOne 金屬材料公告的觀點,由ExOne 公司首席執行官John F. Hartner 發表於2020 年2 月25 日。Metal 3D Printer Materials. ExOne metal binderjetting systems now print 21 metal, ceramic andcomposite materials. Three levels of qualification now offered for different market needs.本文論及ExOne 的金屬3D 列印材料。以黏結劑噴射為主的技術,現在可以列印21 種包含金屬、陶瓷與複合材料的類別。有三個階段的品質提供給不同市場的需求。其中,最大好處在於可使用第三方(Third-Praty)粉末,大大增加工程設計師對產品材料選型的範圍,也大幅降低了材料成本,只要符合ExOne 的材料規格,客戶可以享受到更多好處。

Today, ExOne announced its metal 3D printerscould now binder jet a total of 21 powders intometal, ceramic and composite precision parts –with even more materials approved for controlled R&D printing.

今天,ExOne 公布了現在可列印21 種包含金屬、陶瓷與複合材料所建構的精密零件,甚至有更多的材料在我們研發部中緊鑼密鼓的進行。

From the outside, it may look like ExOne’s metalprinters jumped from six to 21 qualified materialsovernight. In reality, ExOne’s engineering team and our customers have been moving so fast to print new materials since 2013 — the breakthrough year when we began printing dense single-alloy metals — that we haven’t slowed down to update the market on our progress.從外部看來,ExOne 的金屬3D 列印機可能是一夜之間從6 種躍升至21 種合格的材料。實際上,自2013年以來,ExOne 的工程研發團隊和我們的客戶一直在快速列印新的材料,這是我們開始列印緻密度更高的單一合金金屬最有突破性的一年。因此,我們並沒有放慢速度,持續更新以符合市場的進展。

When we took the time to re-evaluate where we were over the last few months, the numbers surprised even us. ExOne customers were printing an astonishing number of materials — 14 — that had not yet worked all the way through ExOne’s rigorous qualification process. That included six single alloys, six ceramics, and two ceramic-metalcomposites.當我們花時間審核我們過去幾個月的情況時,這些新材料的總數甚至使我們感到吃驚,ExOne 的客戶正在列印數量驚人的材料種類多達「14 種」,這些材料在 ExOne 嚴格的認證過程中卻一直未能奏效。其中包括6 種單一合金、6 種陶瓷和2 種陶瓷- 金屬複合材料。

At the same time, we were ready to announce new materials, such as M2 Tool Steel, had achieved our highest qualified status, and other materials, such as aluminum and titanium, were qualified for controlled R&D printing. So, a major reset was needed.同時,我們準備宣佈新材料,如M2 工具鋼,已達我們的最高合格標準。其他材料,如鋁和鈦,也正在研發列印並被列為可能合格之選項。因此,我們需要針對ExOne 能夠製作的材料表進行重大重置。

圖2:ExOne 首席執行官John F. Hartner 先生;圖3:按需求列印的3D 列印金屬零件

ExOne 的嚴格資格認證流程

E xOn e ’s t o p – t i e r q u a l i f i c a t i o n p ro c e s s i s deliberately very tough – it’s meant to designate that customers can buy a metal printer and, essentially, have standardized 3D printing with repeatable results out of the box. We also get these results certified by a third party, which is why we call this our “Third-Party Qualification” level.ExOne 的最高級認證流程非常的嚴格,它意味著客戶可以購買金屬列印機,並且基本上具有標準化的3D列印功能外,還具有開箱即用的可重複結果,加上我們還獲得第三方認證的這些結果,這就是為何我們稱之為我們的「第三方資格」級別。

Binder jetting uses an industrial printhead to quickly deposit a liquid bonding agent onto a thin layer of powdered particles, either metal, sand, ceramics or composites. The process is repeated, layer by layer, until the object is complete. Depending on the material being printed, additional post-processing may be necessary.

黏結劑噴射系統是採工業列印頭快速將液體黏結劑噴射使其沉積在一層薄薄的粉末顆粒上,包括金屬、砂粒、陶瓷或複合材料。該過程逐層重複,直到物件完成。根據所列印的材料,可能需要額外的後處理。

Overall, the binder jetting process is simple. But optimizing the machines, binders, powders and post-processing steps to work together to deliver the precise densities, material properties and metallurgy the market wants with every powder is serious engineering work. At ExOne, we won’t third-party qualify a material until we’ve truly achieved top-tier results repeatedly.總體而言,黏結劑噴射過程非常簡單。但必須優化機器、黏結劑、粉末和後處理步驟,以協同工作,提供市場上客戶對每種粉末所希望的精確密度、材料特性和冶金結果,這是一個嚴肅的工程作業。在ExOne,除非我們多次獲得頂級結果,否則我們不會對材料進行第三方資格認證。

F o r e x a m p l e , e v e n b e f o r e w e m a d e t h i s announcement, our team was debating whether Inconel 718 should receive our top-tier qualification. We routinely print this material in R&D, and we’re very close to where we want to be with the material. But for now, we’ve decided it still belongs on our list of qualified R&D materials until we’ve fully optimized the end-to-end process.例如,在我們發佈此公告前,我們的團隊還在討論Inconel 718 是否應獲得我們的頂級資格。我們經常在研發中列印這種材料,而且我們非常接近我們想要使用這些材料的位置。但是現在,我們已經決定它仍屬於我們的合格研發材料清單,直到我們完全優化端到端流程。

客戶認證材料

In the meantime, many of ExOne’s customers have been printing the powder they needed because it meets their own standards, which are different than ExOne’s broad commercial-readiness standard. Usually, these requirements are very specific to a certain application and not general to the overall marketplace.

與此同時,ExOne 的許多客戶一直在列印他們需要的粉末,因為它符合他們自己的標準,這與ExOne 廣泛的商業準備標準不同。通常這些要求非常特定於某個應用,而非整個市場的通用要求。

表1:第一級,第三方認證的材料

表1:第一級,第三方認證的材料

Really, that’s the beauty of binder jet 3D printing: you can print almost any powder if it works with a binder and delivers the final material properties required. So, with our announcement today, ExOne is launching a new qualification category called “Customer-Qualified.” This means the material is printable on our machines and that customers are successfully printing it today for their own applications. We felt this was necessary to let the market know all the materials that are printable, so others might take advantage of the sustainability and design benefits of binder jet 3D printing for their parts and products.真的,這就是黏結劑噴射3D 列印的美妙之處:若黏結劑與粉末鋪粉器一起工作,並提供所需的最終材料屬性,您幾乎可以列印任何粉末。隨著我們今天的公告,ExOne 將推出一個新的資格類別,稱為「客戶資格」。這意味著材料可在我們的機器上列印,並且客戶今天已成功將其列印用於自己的應用。我們認為,這是必要的。讓市場知道所有材料是可列印的,所以其他人可能會利用黏結劑噴射來進行3D 列印的可持續性和設計優勢,完成他們的零件和產品。

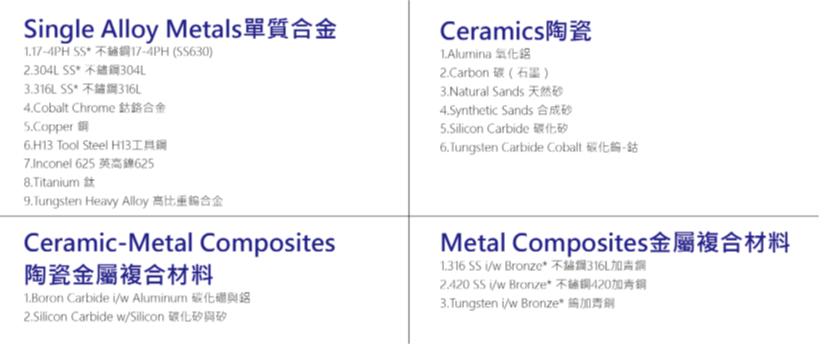

Exciting materials are on this list, such as cobaltchrome, copper, H13 Tool Steel, Inconel 625,titanium and tungsten heavy alloy. Customers arealso printing ceramics such as alumina, carbon,natural and synthetic sands, silicon carbide, alone or infiltrated with silicon, tungsten carbide-cobalt. We’ve also previously announced our work with Oak Ridge National Laboratory on boron carbide infiltrated with aluminum.

令人振奮的材料列在以下的清單中,如鈷鉻、銅、H13 工具鋼、Inconel 625、鈦和鎢重合金。客戶還列印陶瓷,如氧化鋁、碳、天然和合成的砂(作為鑄造產業用的砂芯)、碳化矽、單獨或滲透矽、碳化鎢鈷。我們之前也宣布我們與橡樹嶺國家實驗室合作,處理碳化硼滲透鋁。

Copper is a good example of the work our customers have been doing. Virginia Tech Prof. Chris Williams, Ph.D., has been 3D printing copper on ExOne machines since 2015, starting with the ExOne R2 machine, launched in 2003, and now also with an Innovent®, a machine launched in 2018 for high-density metals printing. Prof. Williams’ work on the subject of copper printing with ExOne binder jet printers has been published in at least three peer-reviewed journals, including Design &Materials, Additive Manufacturing, and Procedia Manufacturing.

銅材料是客戶一直從事的一個很好的應用例子。佛吉尼亞理工大學教授Chris Williams 博士自2015 年起在ExOne 機器上進行3D 列印銅,從2003 年推出的ExOne R2 機器開始,現在又推出了Innovent®,該機器於2018 年推出,可用於高密度金屬列印。關於使用ExOne 黏結劑噴射列印機進行銅列印工作的相關研究,Williams 教授已在至少三份同行評審的期刊上進行發表。

表2:第二級,客戶合格材料

表2:第二級,客戶合格材料

So, while ExOne hasn’t fully qualified copper for our top-tier status, it will likely work for many customer applications – depending on the specific requirements needed. The Benefits of Binder Jetting. We’re excited about today’s change in material classifications — not because it results in an impressive number of printable materials — but because it showcases the great diversity that binder jetting offers in terms of material and design flexibility, and sustainability.因此,雖然ExOne 尚未完全獲得頂級狀態的銅製品,但它可能適用於許多客戶應用,而這具體取決於客戶所需的特定要求,這也是黏結劑噴射列印法的好處。我們對當今材料分類的變化感到興奮,不是因為它帶來了數量可觀的可列印材料,而是因為它展示了黏結劑噴射在材料和設計靈活性方面提供的巨大多樣性,以及可持續性。

Binder jet 3D printing is a sustainable method ofmetal part production because it fabricates objects with little to no waste, and, at the same time, enables all-new lightweight designs that were not previously manufacturable. What’s more, binder jetting is capable of 3D printing parts at high speeds and volumes that can truly make a difference. At ExOne, where we’ve always been proud to be green, more binder jetting materials will eventually mean more sustainable manufacturing and products for all.黏結劑噴射3D 列印是種可持續的金屬零件生產方法,

因為它可製造幾乎或沒有浪費材料的物體零件,同時支援以前無法製造的所有全新輕質設計。此外,黏結劑噴射能高速且大批量3D 列印零件,能夠真正發揮作用。在ExOne,我們以環保為榮,更多的黏結劑噴射材料最終將意味著更可持續的製造和產品。

金屬3D 列印系統:材料與黏結劑

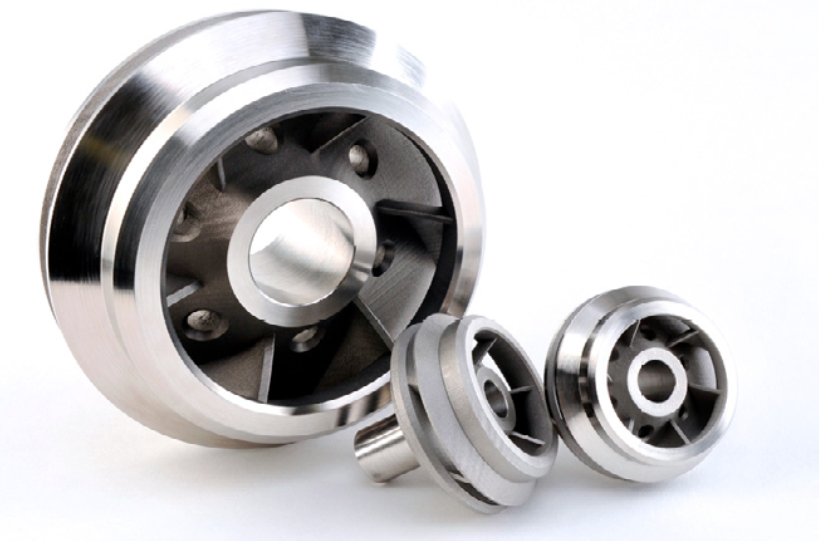

ExOne metal 3D printers transform more than 20 powders into metal, ceramic and composite parts and products. Our metal printing technology creates dense and functional precision parts used for automotive, aerospace, defense, energy, and consumer applications.ExOne 金屬3D 列印機將20 多種粉末轉化為金屬、陶瓷與複合材料零件和產品。我們的金屬列印技術可製造使用於汽車、航空航太、國防、能源和消費類應用的密集和功能精密零件。

To ensure customers will have reliable, repeatable and predictable parts, from 3D printing to final sintering, we have a comprehensive qualification process. ExOne’s R&D teams work continuously to qualify new materials for use in our machines. What’s more, we routinely partner with companies to develop specific materials for binder jet 3D printing with our technology. ExOne has three qualification levels that recognize different degrees of readiness for customers with different application needs.為了確保客戶擁有可靠、可重複和可預測的零件,從3D 列印到最終燒結,我們進行了全面的認證流程。ExOne 的研發團隊不斷努力,使新材料符合用於我們的機器的資格。此外,我們經常與公司合作,利用我們的技術開發用於活頁夾噴頭3D 列印的特定材料。ExOne 有三個資格級別,可識別不同應用需求的客戶之不同準備程度。

第一級:第三方認證的材料

These materials have passed ExOne’s rigorous testing for uniformity, dimensional tolerance, sintering characteristics, and other features over multiple builds. Please see the attached data sheets for third-party testing results based on MPIF standards.表1 中的這些材料已通過ExOne 的嚴格測試,在多個構建中具有均勻性、尺寸容差、燒結特性和其他特徵。基於MPIF 標準得出的第三方測試結果,請參閱機器說明書隨附的數據表。

第二級:客戶合格材料

The materials below have been qualified for use by ExOne customers, using standards for their own applications, and are being successfully printed today. Additionally, a number of ExOne customersn also print proprietary powdered materials on our machines that are not listed below. If you have a question about 3D printing the materials below, please contact us.表2 的材料是客戶端已使用於自己的應用上,並建立一套自己的標準,且已成功進行列印(但未通過嚴格的第一級ExOne 認證)。此外,許多ExOne 客戶還在我們的機器上列印沒有列於表2 的專有粉末材料。若您對表2 材料的3D 列印有疑問,請聯繫我們。

表3:第三級,研發中的材料

第三級:研發中的材料

These materials have been deemed printable by ExOne and our customers after preliminary analysis. Our R&D work for these materials is ongoing and involves engineering work with the materials, as well as our printers and processes, to ensure successful printing. If you are interested in collaborating on development of these or any unlisted materials, please contact us.經初步分析,ExOne 和我們的客戶認為表3 這些材料可以列印。我們對這些材料的研發工作正在進行中,涉及材料以及印表機和工藝的工程工作,以確保列印成功。如果您有興趣合作開發這些或任何沒有列於表3 中的材料,請聯絡我們。

ExOne 的觸媒黏結劑

One of the reasons ExOne metal binder jet systems can print such a diversity of powdered materials is our portfolio of specialty Fuse binders, which deliver unique benefits for the material being 3D printed.

ExOne 金屬黏結劑噴射系統能夠列印如此多樣化粉末材料的原因之一是因為我們的專用觸媒黏結劑產品組,為3D 列印材料提供了獨特的優勢。

Binders must deliver certain characteristics thatwork harmoniously with the powder material being printed. Considerations include viscosity, saturation, bleeding in X and Y, as well as de-binding characteristics. ExOne binders continue to be optimized to provide improved green strengths and other beneficial properties based on the materialbeing printed.黏結劑必須提供與所列印粉末材料和諧工作的某些特性。該注意事項包括粘度、飽和度、X 和Y 中的出血(邊界的清晰度,不好的黏結劑容易渲染超出設定的邊界,出血就是印刷的突出邊界的意思)以及脫粘特性。ExOne 黏結劑噴射繼續經過優化,以便根據所列印材料提供改進的綠色強度和其他有益特性。

• CleanFuse:

A premium, clean-burning binder that leaves behind no carbon residue and works well with metallic materials negatively affected by carbon, such as Inconel powders.優質、清潔燃燒的粘合劑,不留下任何碳殘留物,並可很好地處理受碳負面影響的金屬材料,如Inconel粉末。

• FluidFuse:

A versatile solvent-based binder with low viscosity that works well with a variety of metallic and nonmetallic materials, including ceramics.一種多功能溶劑基粘合劑,粘度低,適用於各種金屬和非金屬材料,包括陶瓷。

• AquaFuse:

A water-based binder that works well with a variety of metallic material.水性粘合劑,可與各種金屬材料配合良好。

• PhenolFuse:

A phenolic binder best suited for printing hightemperature materials, including non-metallics such as carbon, tungsten carbide (WC), silicon carbide (SiC), and other ceramics.最適合印刷高溫材料的酚類粘合劑,包括非金屬材料,碳、碳化鎢(WC)、碳化矽(SiC) 和其他陶瓷。■

原文資料:由ExOne 的中國代理商合肥新杉航宇三維科技有限公司提供

項目經理:梁偉

E-mail:wei.liang@sinsun-tech.com