■ ACMT/ 邱耀弘

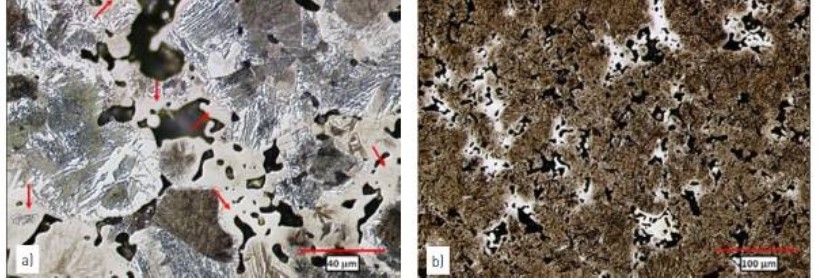

2.4 Revealing the microstructure顯微組織的顯露

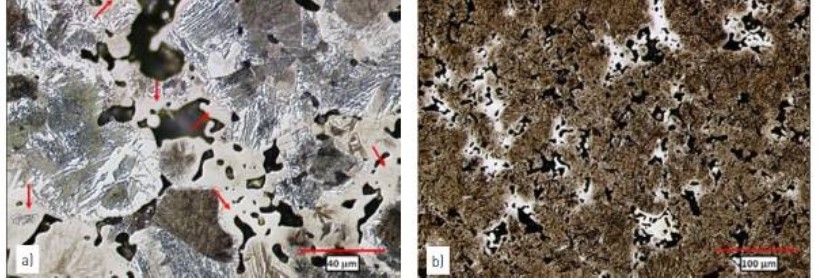

The chemical etching process used to reveal themicrostructure in PM alloys is the same as for other metallic materials. With ferrous PM alloys, the transformation products are the same as those seen in wrought and cast steels. Ferrite, Pearlite, Bainite, Martensite and retained austenite are observed, although their distribution in the part volume may be somewhat different due to the locations and distribution of the alloying additives. As was discussedearlier, some of the peculiarities observed with PM alloys derive from the methods and materials used for alloying. High additive concentrations sometimes result in alloy-rich areas, such as the Ni-rich regions observed in admixed or diffusion-alloyed powder mixtures made using elemental nickel as an additive. The nickel particles diffuse slowly at normal sintering temperatures and often create regions that do not appear to transform during cooling. These highnickel- content regions, as observed in P2-Fig.7, are also more resistant to the dilute etchants typically used to reveal the microstructure and appear as flat, featureless or nearly featureless regions (see arrows) in P2-Fig.7a and white, un-etched areas in a martensitic matrix in P2-Fig.7b.粉末冶金零件的化學蝕刻處理和其他金屬材料的過程是一樣的。粉末冶金鐵基製品的相變產物與傳統加工件、鑄造件也是一致的,合金元素分佈上的差異可能會使PM 零件中各種組織的分佈形態與傳統鋼材有一些不同,但諸如鐵素體、珠光體、貝氏體、馬氏體以及殘餘奧氏體等這些鋼材中的典型組織在PM 零件中都是可以觀察到的。前面已經提到,粉末合金化的途徑會影響到影響到燒結PM 合金材料的組織特徵,採用元素法或部分預合金法來製備混合粉末原料,在PM 燒結件中就可能出現一些合金元素的富集區。比如若採用純鎳粉作為合金元素加入粉末混合體中,在燒結零件中就可以觀察到一些富鎳區。在正常燒結溫度下,鎳顆粒的擴散溶解速度是比較慢的,冷卻後經常能夠看到一些未完全溶解到基體中的富鎳區。如P2- 圖.7a 所示,這些富鎳區幾乎不被蝕刻劑腐蝕,在金相圖片上表現為無細節或很少細節的白亮區域( 圖中箭頭所指);P2- 圖.7b 則是觀察到未被蝕刻的麻田散組織。

The same chemical etchants and techniques are used with ferrous PM materials as for other ferrous alloys. Nital and picral are the most commonly used etchants. Excellent sources of information about etchants, such as compositions, method of application and uses are shown in the recommended reading section of this article. Of particular note are Vol. 9 of the ASM Handbook series, Metallography and Microstructures, and Metallography Principles and Practice by George Vander Voort.粉末冶金鐵基材料所用的化學蝕刻劑與傳統鋼材是一樣的,其中以硝酸蝕刻劑和苦味酸蝕刻劑應用最普遍。在本文的推薦閱讀部分可以找到各種蝕刻劑的配方、用法等大量豐富的資訊,特別推薦由George Vander Voort 編寫的ASM 手冊第九卷:金相與顯微組織,金相判定準則與實踐。

Etching is normally accomplished with either a single-step application of a dilute acidic or basic solution to a freshly prepared sample surface or the deposition of an interference film (stain), which preferentially coats specific areas in the microstructure. When using the staining technique, the surface is often lightly pre-etched with a dilute acidic or basic solution before an interference layer is deposited on the pre-etched surface.蝕刻過程既可以是簡單地用稀釋的酸或堿溶液溶解掉樣品表面的部分材料,也可以是在特定區域沉積一層著色膜( 色斑)。採用著色技術時,通常會先用稀釋的酸堿溶液對樣品表面進行輕度腐蝕,然後再加以著色。

When applied correctly, particular features stand out and are accentuated due to variations in the thickness of the precipitated layer. With most etchants, the cleaner the prepared surface, the more effective and uniform the etched surface.正確的著色可以使不同物相上的沉積膜厚度產生差異,從而使特殊的組織特徵被明顯地顯露出來。對多數蝕刻劑來說,樣品原始表面越清潔,蝕刻效果越顯著、越均勻。

2.4.1 Single step etching 簡單蝕刻

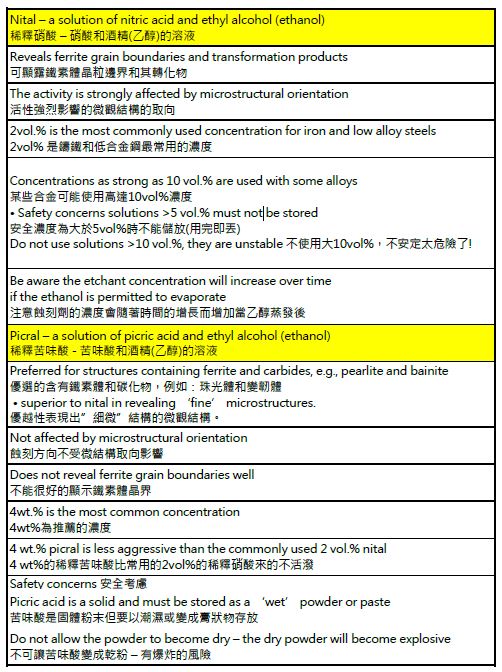

The simplest and most of ten used etching techniques involve a single application of an etchant to the sample surface. As stated previously, the most frequently used etchant compositions for the ferrous materials are nital and picral. The two etchants are similar in their activity with the ironbased alloys, but each has strengths compared

with the other. They may be used as stand-alone etchants or mixed into a nital + picral solution to realise the benefits of each. A brief listing of the attributes for the two etchants are shown in Table 1.

P2-Fig.7 Hybrid alloy with a 0.85 wt.% Mo prealloy base + 4 wt.% elemental Ni + 0.5 wt.% graphite (FLN4-4405).

P2-Fig.7 Hybrid alloy with a 0.85 wt.% Mo prealloy base + 4 wt.% elemental Ni + 0.5 wt.% graphite (FLN4-4405).

Image (a) as sintered; Image (b) quench-hardened & tempered (2 vol.% nital + 4 wt.% picral混合的合金為0.85 wt% 鉬預合金+ 4 wt% 純鎳元素+ 0.5 wt% 石墨(FLN4-4405),其中影像(a) 為燒結後、 (b) 淬火硬化與時效處理後(2 vol% 稀釋硝酸+ 4 wt% 苦味酸)

Examples of surfaces etched using the combination of 2 vol.% nital and 4 wt.% picral are shown in Figs. 1, 5 and 7. They illustrate the effectiveness of this combination over a wide range of alloy compositions and microstructures. Interestingly,the copper steels present a unique set of minor problems when etched with nital and the nital-picral combination.

最簡單、應用最廣泛的蝕刻技術就是用一種蝕刻劑對樣品表面進行處理。如前所述,對鐵基材料而言最常用的蝕刻劑有硝酸蝕刻液和苦味酸蝕刻液,也可以混合使用來獲得最佳的樣品處理效果。

這兩種蝕刻劑對鐵基材料的總體蝕刻效果相當,當然也有各自的長處亦可單獨使用,對兩蝕刻劑的屬性的簡短清單如表1 所示。例子的表面蝕刻用2 體積% 的硝酸和4 重量% 苦味酸酒精溶液所示的組合。 7.5 和1。他們說明了這種組合的有效性,在很寬的範圍內的合金成分和微

觀結構。有趣的是,銅鋼提出了一套獨特的小問題時用硝酸和硝酸蝕刻苦醇組合。

Table 1 Attributes of the most frequently used etchant compositions for the ferrous materials, nital and picral

( 右圖表) 最常使用的蝕刻劑組合物的有色金屬材料屬性、硝酸、苦味酸酒精溶液

Since the elemental copper additions become liquid at normal sintering temperatures and diffuse along austenite grain boundaries and pore edges in the powder base, these areas have the highest Cu content. When the nital etchant is applied to the surface, the Cu-rich ferritic regions respond by staining brown and do not retain the typical white ferrite appearance. The presence of the Cu also increases the speed of etching, in some cases giving the operator little flexibility in the time between having a properly etched sample and one that is over-etched. This staining can be seen at the locations indicated by the arrows in P2-Fig.8(a), which illustrates an Fe-Cu-C alloy sintered for a time of only 5 minutes at 1120 ° C. This microstructure contains ferrite, pearlite, free Cu and porosity. P2- Fig.8(b) is a second example, in this case illustrating a Cu-infiltrated Fe-Cu-C material. In both cases, the brownish staining is apparent. The difficulties resulting from this staining include a masking of the structure within the brownish ferrite (usually pearlite or bainite) if the sample is heavily etched.有趣的是,對燒結銅鋼而言,採用硝酸或硝酸- 苦味酸混合蝕刻劑會帶來一些小問題。以元素法加入的銅粉末在常規燒結溫度下會形成液相,並沿著奧氏體晶界或孔隙邊界進行擴散,使得這些位置具有最高的銅含量。如果用硝酸蝕刻液對樣品表面進行處理,富銅的鐵素體區會變成褐色而不是通常的白色。銅的存在還會大大加快腐蝕速度,稍不注意就會發生過腐蝕,操作者很難把握合適的蝕刻時間。

P2- 圖.8a 所示為一種Fe-Cu-C 合金在1120℃燒結5分鐘並蝕刻處理所得的金相圖片,其顯微組織中包含鐵素體、珠光體、游離銅和孔隙,箭頭所指的位置就是褐色的富銅鐵素體相。 P2- 圖.8b 是另一種浸潤了銅的Fe-Cu-C 合金金相圖片。兩幅圖片中都可以明顯看到由於銅的存在而產生的褐色區域。

The difficulties resulting from this staining include a masking of the structure within the brownishferrite (usually pearlite or bainite) if the sample is heavily etched. The dark stain may result in a possible misinterpretation of the microstructure when examined at lower magnifications, where, if not verified at higher magnification, these brownish areas may mistakenly appear to be a fine pearlite orbainite microstructure. A change in the composition of the etchant to a combination of 1 vol.% nital and 4 wt.% picral, reducing the concentration of the etchant, gives the operator more latitude with the time needed for etching. The samples in P2-Fig.8 were etched with this diluted nital-picral solution to control the speed and depth of staining while revealing the pearlite accurately.這種著色效果帶來的問題是,如果樣品被過度腐蝕,那麼在褐色鐵素體相中存在的其它組織特徵(通常是珠光體或貝氏體)就會被掩蓋。觀察低倍金相時,較深的著色效果可能會引起對樣品組織的誤判,比如把褐色區域錯判為細小的珠光體或貝氏體組織。將混合蝕刻液中硝酸的比例降低,可以減緩腐蝕的速度,使操作者有更寬的操作範圍來調整適當的蝕刻時間。

P2-Fig.8 Iron-copper-carbon samples showing the brown stain resulting from Cu diffusion in ferrite. Image (a)

P2-Fig.8 Iron-copper-carbon samples showing the brown stain resulting from Cu diffusion in ferrite. Image (a)

sample sintered for five minutes where the Cu diffusion distances are limited due to the short sintering time

and (b) a fully sintered, Cu-infiltrated sample (1 vol.% nital + 4 wt.% picral)鐵- 銅- 碳樣品顯示鐵素體中的銅在鐵素體中的擴散引起的棕色斑。圖(a) 樣品為燒結5 分鐘後在銅擴散的距離是有限,由於燒結時間短和圖(b) 一個完全燒結、滲銅樣品( 蝕刻劑為1 vol% 稀釋硝酸+ 4 wt% 稀釋苦味酸)

P2- 圖.8 中的樣品就是採用這種稀釋了硝酸組分的蝕刻液進行處理,著色的速度和深度得到較好的控制,最終圖像中能夠非常準確地分辨出珠光體組織。

While nital and picral are the most commonly used etchants, other etchants formulated for general use or designed to reveal specific features are also used. Several of the reference books listed at the end of this article contain extensive lists of etchants and should be consulted as needs arise.硝酸、苦味酸酒精溶液是最常用的腐蝕劑,其他腐蝕劑或其他制定出具體的功能也可用。幾個本文末尾列出的參考書包括蝕刻劑廣泛的清單,有需要時可做為參考之用。

2.4.2 Deposition of an interference layer干涉膜沉積

With PM steels, stain etching usually uses a combination of a dilute acid pre-etch (nital, picral or a combination of the two) to roughen the freshly prepared surface followed by immersion in an aqueous solution designed to deposit an oxide, sulphide, sulphate or molybdate interference layer onto the pre-etched surface. This layer appears as a controlled stain with the composition and thickness determined by the local chemical composition, transformation product, phase, microstructural/ crystal orientation, exposure time, etc. at the sample surface. As the thickness changes locally, the colour resulting from interaction of the light with the interference layer also changes. Several examples are included that illustrate the use of these techniques with PM materials.

粉末冶金材料的蝕刻- 著色技術通常包括以下過程:首先以稀酸( 硝酸、苦味酸或兩者的混合物) 對樣品表面進行預蝕刻,使其粗糙化,然後將樣品浸入特製的著色液中,使樣品表面沉積出氧化物、硫化物、硫酸鹽、鉬酸鹽等,形成乾涉膜。樣品局部的化學成份、相變產物、晶格取向、著色時間等都會影響到沉積產物的成分和厚度,進而使這些區域顯示出特定的顏色。當乾涉膜的厚度發生改變時,由於光線和乾涉膜的相互作用,會使得相應區域的顏色發生改變。下面展示幾組運用這項技術的金相實例。 ■